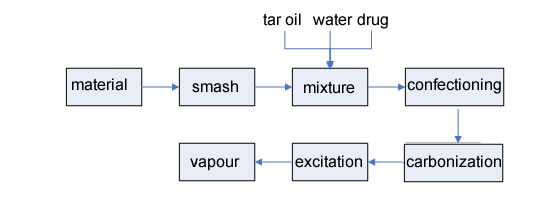

Principle and application Gas method (H2O, CO2) manufacture of Suzhou air purification activated carbon has little pollution to the environment and is convenient for mass production. However, the pore distribution of activated carbon produced by gas method is small, resulting in low BWC (butane working capacity) during gas phase adsorption; Liquid phase adsorption; Unable to remove contaminants from larger molecules in the water. The method is produced in the gas method on the basis of adding a small amount (2%-6%) of alkali metal halides and alkali metal oxides in the material to stir evenly, and then drying, crushing, forming, using these substances at high temperature (800℃ -950 ℃) on the corrosion of carbon, so that the pore distribution of activated carbon widened. The manufacturing process is as follows:

Example 1, using coal as raw material: the process is the same as that of cylindrical activated carbon production, only 2%-6% (WT) of alkali metal halides are added in the mixing process.

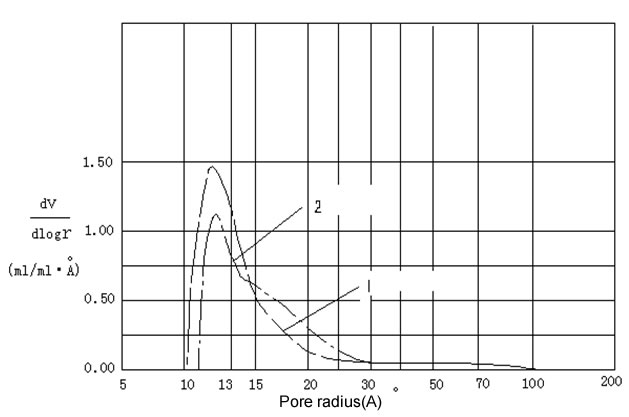

The effect is shown in Figure 1. In curve 1 in Figure 1, the adsorption capacity of benzene is 70%, while BWC=8.26g/100ml;

In curve 2, the adsorption capacity of benzene is 68%, while BWC=9.0g/100ml;

Example 2: After adding 2% to 6% of alkali metal oxides during the production process, the removal rates of the dye Gangan Red (molecular weight 696.68) and the dye Curcumin Blue (molecular weight 960.8) in the wastewater were significantly improved.

Enlarged pore effect diagram 3) Maturity and advancement of the technology: This technology is currently at the leading level in China and has undergone pilot-scale and large-scale production. The products produced have been provided to water plants such as the Pinghu Water Supply Company in Zhejiang Province for advanced water treatment. Users' feedback after use indicates that all performance indicators are superior to those of activated carbon without the addition of chemicals for pore enlargement. The equipment required for enterprises to apply this technology can be produced using the existing activated carbon production equipment of this enterprise. For more details and news, please visit www.vikenton.com.